Our Story

Malcolm Willis 2018 Ltd

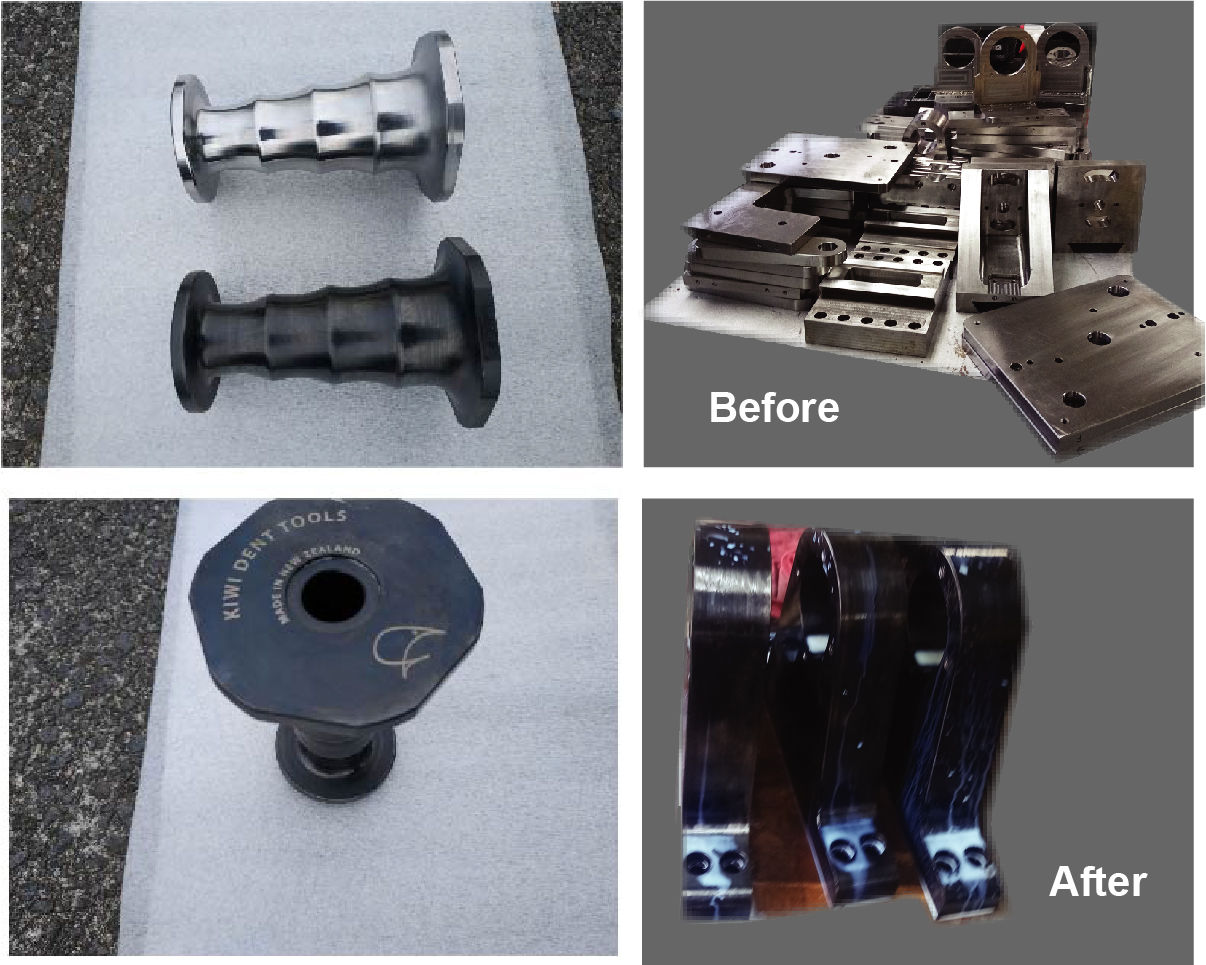

Malcolm Willis 2018 Ltd provides an industrial strength material and component coating service. We are a solution-focused coating specialist company. Assembly, disassembly, coating – we arrange it ALL. From colouring screws to Molybond coating bolts or lawn mower blades.

Chemical coating

Wet spray coating

Other categories

Metal finishing & coating

Protective & Anti-Corrosive Coatings

Metal Sprayers